Family Owned. Globally Proven.

A Footprint Built for Your Success

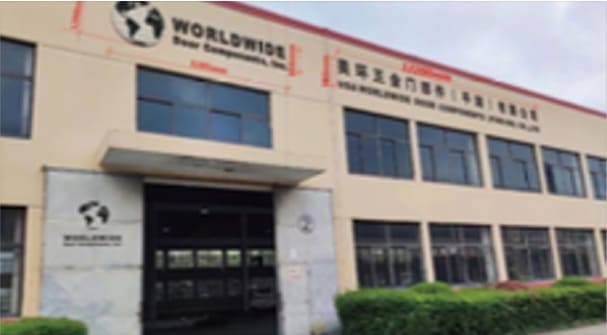

Walk through our Pinghu facility and you’ll see 30 production lines running products for customers across America and the world. Our teams in Indonesia focus on perfecting weatherstripping.

Proud Members of

Real Facilities, Real People

Back in the United States, we’re uniquely positioned with facilities in Arcadia, Florida, Saginaw, Texas, and Lake Village, Indiana – strategically placed to ship products quickly while helping you save on common carrier expenses. Back home in Arcadia, Florida, we handle final touches including machining to spec, quality checks, and U.S. distribution.

And at our corporate headquarters in Lutz, Florida, we cover the entire U.S., bringing everything together under one roof. Our nationwide footprint means we’re not just everywhere… you’re supported in the most efficient, cost-saving way possible.

It’s not just about having facilities around the world. It’s about having the right people in each location who understand the technical requirements, the urgency of your deadlines, and the importance of every single customer.

Invested in Excellence

Since 2014, we’ve invested $2.7 million in new equipment – resulting in tighter tolerances, faster turnaround, and fewer defects. Every investment is made to keep your projects moving and your quality consistent.

Corporate Office

Lutz, FL

Manufacturing & Distribution Facility

Arcadia, FL

Distribution Facility

Fort Worth, TX

Distribution Facility

Lake Village, IN

China Manufacturing Facility

Pinghu Main

China Manufacturing Facility

Pinghu Secondary

Indonesia Manufacturing Facility

Tangerang

The Advantage of Scale

We can handle the big orders that overwhelm smaller suppliers, and we care enough to make smaller orders profitable, too. Whether you need 5,000 jambs or 100 custom thresholds, you get the same attention to detail. Multiple locations mean if one facility encounters an issue, your order keeps moving at another. That’s the kind of built-in backup plan you only get from a supplier that owns the process from start to finish.

At Worldwide, scale isn’t just about size, it’s about the precision, consistency, and speed our customers depend on. Our China facilities are equipped with state-of-the-art automation to keep every order on time and to spec.

Advanced Technology & Capacity

- 23+ extrusion production lines for high-volume precision manufacturing.

- Automatic painting, notching, and wood grain finishing for consistent, repeatable quality.

- Computer-controlled mixing operations for uniform materials and improved production capacity.

- Automated racking system to maintain inventory and ensure year-round, on-time deliveries.

- Expanded product range including new jamb widths, brick moulds, transom parts, and flat stock.

We specialize in our 4Ever Frame® Door Jamb, Patented 4Ever Sill®, Patent Pending EcoLast®, ProT4® Aluminum Threshold, along with a complete product line of hinges, weatherstrip, door sweeps, flushbolts, screws, hardware, and millwork products.

Your Problems Become Our Problems

In manufacturing, something always goes wrong. The difference with Worldwide? We solve it directly… no waiting on outside suppliers, no negotiating with other factories, no passing the blame. We control the machines, the materials, and the timeline. That’s the difference between having a vendor and having a manufacturing partner.